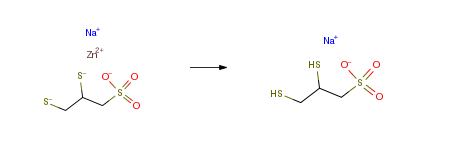

With hydrogen sulfide In ethanol at 18℃ for 4h Reagent/catalyst Large scale

Experimental Procedure

To the 3 L reaction flask was added 2.16 kg kg of 80percent ethanol and 180.0 g (0.66 mol) of the dimercaptosuccinate zinc complex was added under stirring (medium speed) to form a white suspension to control the internal temperature at 18 ± After stirring for 4 hours, 18.0 g of activated charcoal was added to the reactor and stirred for 20 min. The filtrate was filtered in a Buchner funnel. The filtrate was filtered at 60 ± 2 ° C and concentrated to a basic liquid drop. (0.42 mol) of sodium dimercaptopropanesulfonate, titration content of 97.8percent, heavy metal content of 3.0 ppm, yield of 63.5percent.

Step c: Preparation of crude dimercaptopropanesulfonateIn a 100 L autoclave, 64.2 kg of 80percent ethanol was added,A solution of 5.35 kg (19.55 mol) of dimercaptosuccinate sodium complex was added under stirring (medium speed)Forming a white suspension, control the internal temperature at 18 ± 1 , medium speed stirring,Through the hydrogen sulfide gas (ventilation catheter as far as possible into the bottom of the reactor) 10h,Hourly sampling (0.45 micron filter after filtration, diluted 25 times the detection) to detect once,18 hours compared with 17 hours, the amount of sodium dimercaptopropanesulfonate increased by 0.8percent, stop hydrogen sulfide,Add 540g activated carbon to the reactor, continue stirring 20min, discharge to the material barrel,In the Buchner funnel filter, the filtrate 60 ± 2 under reduced pressure to the basic no liquid dripping,2.50 kg (11.89 mol) of sodium dimercaptopropanesulfonate, the titration content was 97.5percent and the yield was 60.8percent.Step d: Sodium dimercaptopropanesulfonateTo the 50 L reactor was added 28.17 kg of 95percent ethanol, 2.45 kg (11.65 mol) of crude sodium dimercaptopropanesulfonate, under the protection of nitrogen, heated to reflux, dissolved, cooled to 70 ° C, adding 24.5 g activated carbon decolorization , The temperature of stirring for 20 minutes, filtered hot, the filtrate slowly cooled to 5 , filtration, ethanol washing, 60 ± 2 vacuum drying to constant weight, to be dimercaptopropanesulfonate purified product 2.26kg (10.75mol), refined Rate 92.2percent, titration content of 99.5percent, heavy metal 3.1ppm. The total yield was 16.1percent calculated by sodium allylsulfonate, and the total yield was 24.2percent calculated by zinc acetate.Example 2 (Preparation of zinc complex of dimercaptopropane sulfonate, without addition of auxiliaries)In the present example, no additional additives were added to the bromine reaction, and the other steps and reaction conditions were the same as those of Example 1, step a and step b.Results: The consumption of sodium hydroxide 1.60kg (40.05mol), zinc dimercaptopropane sulfonate complex: 3.86kg (14.11mol), liquid purity 90.9percent, 95.2percent after deduction of zinc sulfide, calculated as zinc acetate, Yield 30.9percent. | 63.5% |