tetrakis[(epoxycyclohexyl)ethyl]tetramethylcyclotetrasiloxane CAS#: 121225-98-7; ChemWhat Code: 1489948

Identification

Physical Data

| Appearance | Colorless to light yellow transparent liquid |

Spectra

| Description (NMR Spectroscopy) | Nucleus (NMR Spectroscopy) | Solvents (NMR Spectroscopy) |

| Chemical shifts, Spectrum | 1H | chloroform-d1 |

| Description (IR Spectroscopy) |

| Spectrum |

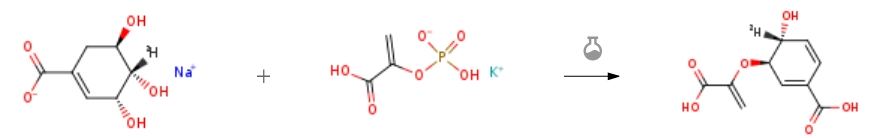

Route of Synthesis (ROS)

| Conditions | Yield |

| 2C8H18S3Cl(1-)Rh(3+) In ethanol; hexane at 95 – 128.5℃; for 4.5h; Heating / reflux; | |

| platinum(II)Cl2(bis(triphenylphsphine)) In dichloromethane; toluene at 123 – 135℃; for 3h; Heating / reflux; Experimental Procedure 2 Example 2. This example describes the preparation of 1,3,5,7-tetrakis(1,2-epoxy-4-cyclohexylethyl)-1,3,5,7-tetramethylcyclotetra-siloxane, DE4, (represented by formula (III)) using parts per billion levels of PtCl2(PPh3)2 as the hydrosilation catalyst. A 1-liter, 3-necked round-bottomed flask equipped with two condensers and a thermometer was charged with VCHO (122 g. 981 mmol).. 49 g (204 mmol) DH4 (1,3,5,7-tetramethylcyclotetrasiloxane), 4 microliters of PtCl2(PPh3)2 catalyst solution (140 ppb Pt based on final product weight) and 83 g toluene.. The reaction solution was heated to reflux with stirring, resulting in a solution temperature of 123°C. At this point the reaction mixture began to reflux vigorously, with the solution temperature reaching 135°C initially, and thereafter settling down at 130°C. The mixture was then refluxed for about 3 hours.. At this point, the infrared spectrum of an aliquot of the reaction mixture showed no Si-H absorption indicating complete consumption of DH4The solution was cooled to room temperature, and the condensers and thermometer were replaced with stopcocks and a short-path distillation head.. The solution was heated with a water bath at 85°C and stripped of volatile components until the vapor temperature was above 70°C. No gel formation was observed during and after the stripping process.. Proton NMR spectrum of the residual material in the reaction flask showed it to be the desired product and free of residual solvent and VCHO. In this manner, 148 g of (III) was obtained as a colorless material. | |

| With potassium chloroplatinate In toluene at 70℃; for 24h; | 75 %Spectr. |

Safety and Hazards

| Pictogram(s) |  |

| Signal | Warning |

| GHS Hazard Statements | H319 (100%): Causes serious eye irritation [Warning Serious eye damage/eye irritation] |

| Precautionary Statement Codes | P264+P265, P280, P305+P351+P338, and P337+P317 (The corresponding statement to each P-code can be found at the GHS Classification page.) |

Other Data

| Transportation | Under room temperature away from light |

| HS Code | |

| Storage | Under room temperature away from light |

| Shelf Life | |

| Market Price |

| Druglikeness | |

| Lipinski rules component | |

| Molecular Weight | 737.241 |

| logP | 8.812 |

| HBA | 8 |

| HBD | 0 |

| Matching Lipinski Rules | 2 |

| Veber rules component | |

| Polar Surface Area (PSA) | 87.04 |

| Rotatable Bond (RotB) | 12 |

| Matching Veber Rules | 1 |

| Use Pattern |

| Tetraepoxycyclohexylethyl 2,4,6,8-tetramethylcyclotetrasiloxane (TCECHTQ) has many advantages in LED packaging, adhesives and 3D printing due to its unique chemical properties and performance. LED Encapsulation: TCECHTQ exhibits excellent transparency, effectively enhancing the optical performance of LED encapsulation materials, ensuring efficient light transmission and reducing light loss. LEDs generate high temperatures during operation. TCECHTQ’s high temperature resistance ensures stability of encapsulation materials under heat, preventing yellowing or decomposition. TCECHTQ can withstand UV radiation and other environmental factors, extending the lifespan of LED encapsulation and maintaining optical performance over time. Adhesives: Its chemical stability allows it to maintain bonding performance across various environments, resistant to chemical agents and environmental changes. TCECHTQ’s elasticity and flexibility enable it to adhere well to diverse materials and surfaces, expanding the applicability and durability of adhesives. 3D Printing: TCECHTQ possesses good flowability and curing properties, enabling high-precision printing suitable for complex structures and detailed requirements in 3D printing models. Its fast curing characteristics improve 3D printing efficiency, reducing printing time and enhancing production efficiency. Improved light efficiency and lifespan in LED encapsulation; increased bonding strength and durability in adhesives; achieving high precision and efficiency in 3D printing. Outstanding weather resistance and chemical stability ensure long-term performance stability in various environments, prolonging product lifespan. |

Buy Reagent | |

| No reagent supplier? | Send quick inquiry to ChemWhat |

| Want to be listed here as a reagent supplier? (Paid service) | Click here to contact ChemWhat |

Approved Manufacturers | |

| Warshel Chemical Limited | http://www.warshel.com/ |

| Want to be listed as an approved manufacturer (Requires approvement)? | Please download and fill out this form and send back to approved-manufacturers@chemwhat.com |

Contact Us for Other Help | |

| Contact us for other information or services | Click here to contact ChemWhat |

![Structure of tetrakis[(epoxycyclohexyl)ethyl]tetramethylcyclotetrasiloxane CAS 121225-98-7](https://www.chemwhat.com/wp-content/uploads/2024/09/Structure-of-tetrakisepoxycyclohexylethyltetramethylcyclotetrasiloxane-CAS-121225-98-7.png)